In the prestige property market, the term “modular” used to be an afterthought. Today, it’s a mark of engineering excellence. We look at why Australia’s most discerning homeowners are choosing factory-precision over traditional site-builds.

For a long time, the Australian dream was built on-site, subject to the whims of the weather, fluctuating trade availability, and the inherent margins of human error. But a shift is happening. Much like a high-end European sports car, the next generation of luxury modular homes is being built in controlled, high-tech environments where millimetres matter.

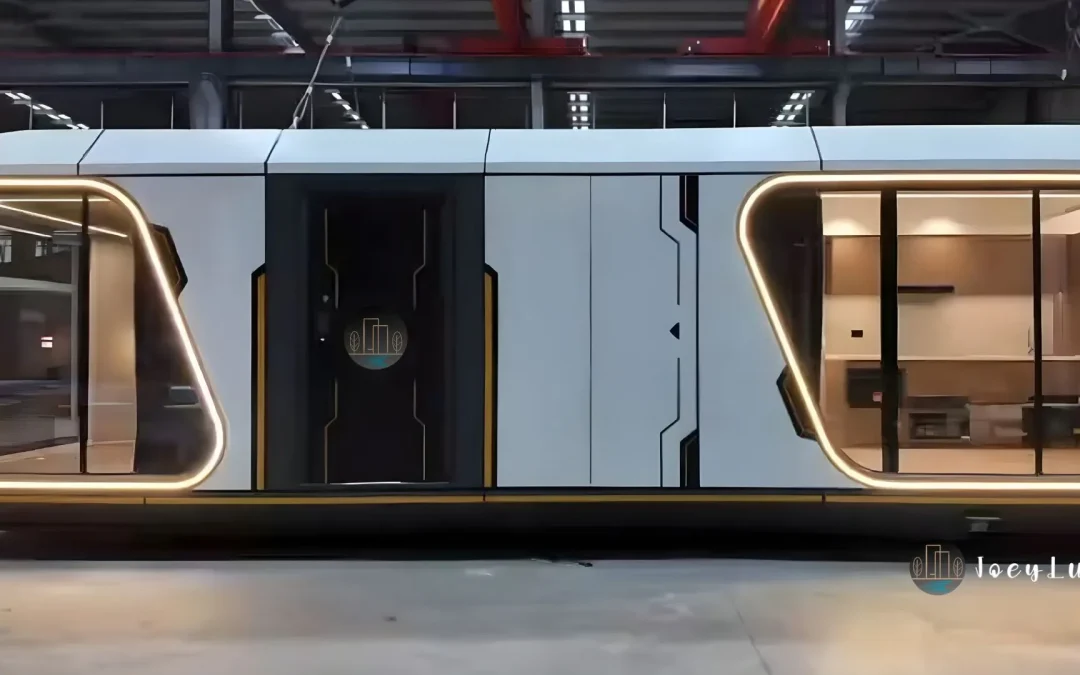

At Joey Luxe, we’ve moved away from the “standard” build. Here’s why precision-engineered architecture is winning the luxury race.

1. The Death of the “Site-Built” Margin of Error

The “Thermal Envelope” Explained

When a house is built on-site, it is exposed to the elements from day one. Timber can warp in the rain, and joints can expand and contract before the roof is even on.

By moving the build into a climate-controlled facility, we eliminate these variables. Our steel frames are engineered to tolerances that are simply impossible to achieve in a muddy paddock. The result? Doors that never stick, perfectly square corners, and a level of structural integrity that far exceeds traditional residential standards.

2. High-Performance Thermal Comfort (Without the Guesswork)

Double Glazing and Solar Orientation

While traditional builds often struggle with “air leakage” due to inconsistent site work, modular homes are sealed with industrial precision.

Instead of focusing on a specific star rating, we focus on Thermal Envelope Integrity. By using high-density PU insulation and Ausralia premium double-glazing in a seamless factory install, our homes maintain stable internal temperatures year-round. It’s about creating a “thermal cocoon” that keeps you cool in a Queensland summer and warm in a Victorian winter—without the massive energy bills.

3. Solving the “Impossible” Site

Minimal Site Disruption

Some of Australia’s most beautiful locations—cliffside lots, remote bushland, or sloping coastal blocks—are a nightmare for traditional builders. The cost of getting trades and materials to these sites often kills the budget before the slab is even poured.

Our

4. Bespoke Finishes as Standard

Shadow-Line Ceilings and Mitred Joints

Luxury is defined by the things you touch every day. In a factory environment, the “fit and finish” are under constant supervision. Whether it’s the seamless integration of custom cabinetry or the flawless application of high-end cladding, the quality control is rigorous.

Industrial-Grade Hardware

When you compare a Joey Luxe interior to a standard

The Verdict

The choice to go modular isn’t about saving time—though that is a significant perk. It’s about choosing a superior method of construction. If you value architectural intent, structural longevity, and a stress-free build process, the factory is the only place your next home should be born.

Ready to see the Joey Luxe difference?

Explore our Architectural Design & Build Quality